Artwork Considerations

Before uploading your artwork, be sure to check out our quick list and full guide below. Use this reference anytime to ensure your designs are print-ready. Carefully review all recommendations before submitting your artwork to avoid any issues in production!

Quick list

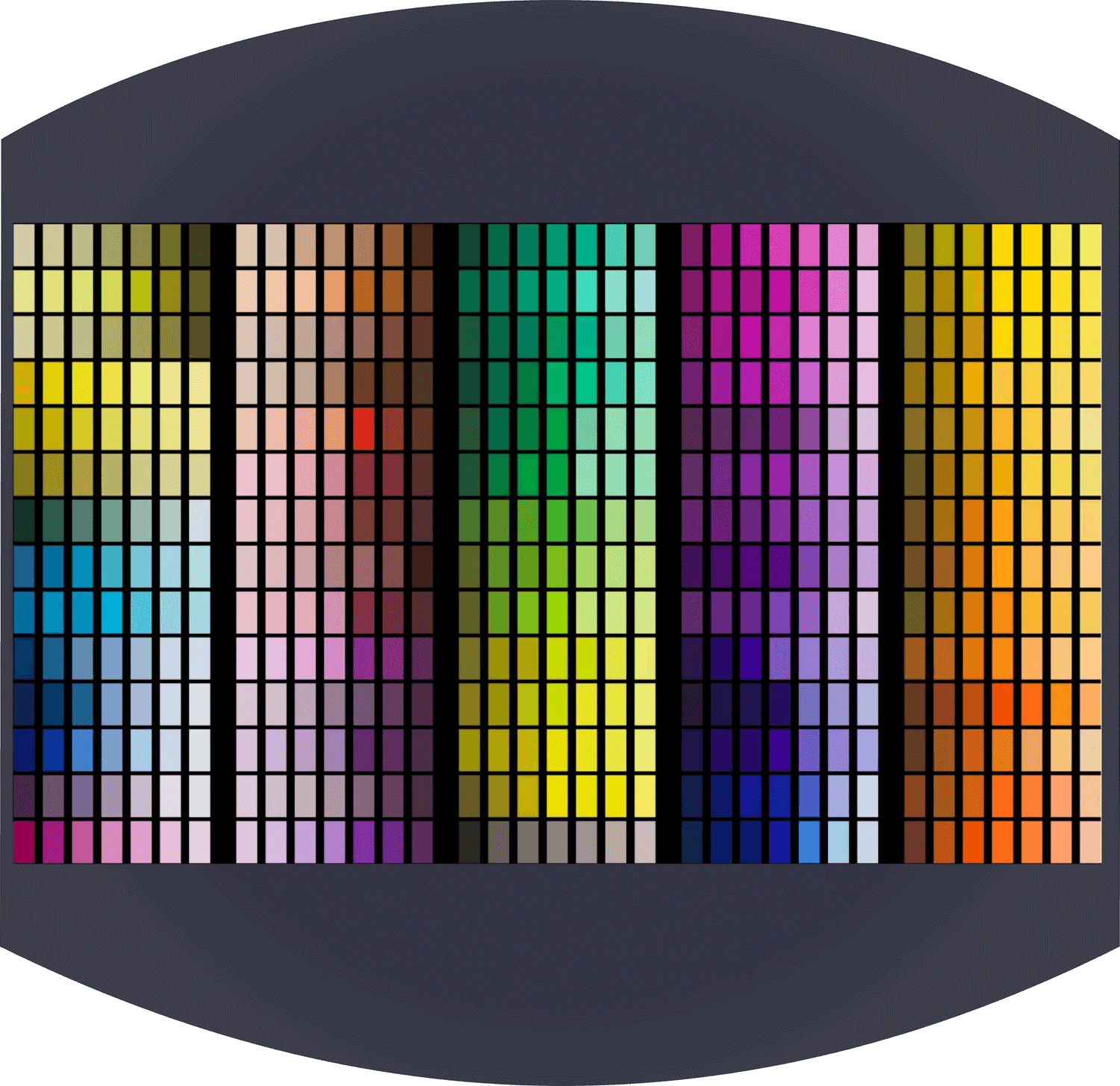

Color Matching

When using these colors in your design make sure to plug these cmyk values into your artwork for true color:

Solid Black -> C:60 M:40 Y:40 K:100

Solid White: -> C:0 M:0 Y:0 K:0

To achieve accurate color matching without a properly calibrated monitor, use the TWZ Master Color Chart. If this chart is not used, designs should be created on a properly color-calibrated monitor to ensure consistency between the digital artwork viewed on your screen and the final printed result. Failure to do so may result in slight color variations in the final print. We do not offer refunds for minor color differences. To ensure satisfaction, we recommend placing a small test order on new designs printed by TWZ before making a larger purchase. Thank you for your understanding.

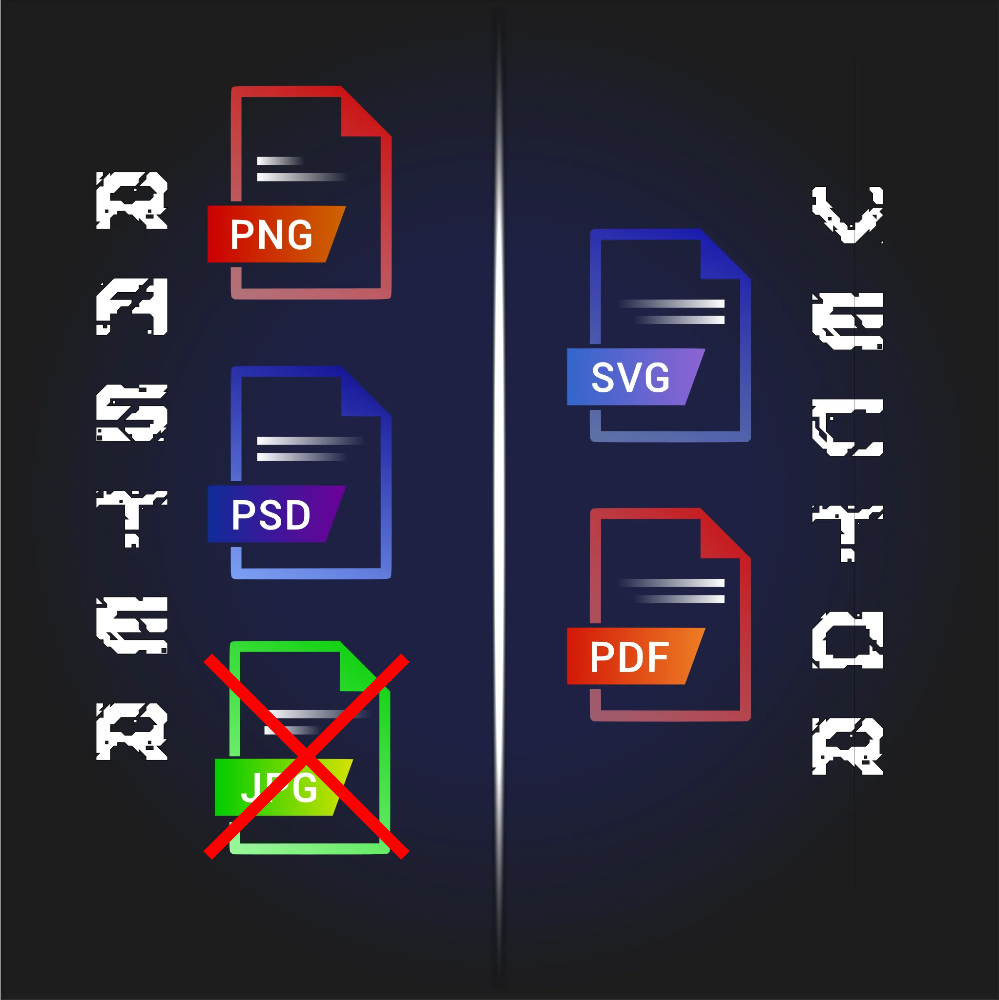

Accepted File Types:

Vector type (.EPS, .AI, .SVG, and .PDF)

Raster type (.PNG and .PSD)

Notes: For the best print quality, vector files are highly recommended. Vector formats such as .EPS, .AI, .SVG, and .PDF are resolution-independent, allowing designs to be resized without pixelation or the introduction of semi-transparent pixels along edges of a design. Raster files such as .PNG and .PSD are composed of pixels and must be handled with care. They cannot be resized without risking pixelation or loss of quality. Any resizing should only be done within design software when creating a new file. Semi-transparent pixels cause an undesirable white haze effect in Direct-to-Film (DTF) printing, when working with raster images always check for semi-transparent pixels along the edges. In your design software remove semi-transparent pixels with a threshold or alpha curve before saving artwork.

Avoiding White Haze Effect

It is strongly recommended to use vector files such as .EPS, .AI, .SVG, and .PDF to prevent the white haze effect that can result with DTF printing and achieve the sharpest, most accurate prints. While raster files like .PNG and .PSD can still be used with great results, they require careful preparation. Before uploading a raster file, always inspect your artwork and remove any semi-transparent pixels, as they can cause a white haze effect and negatively impact the final print quality.

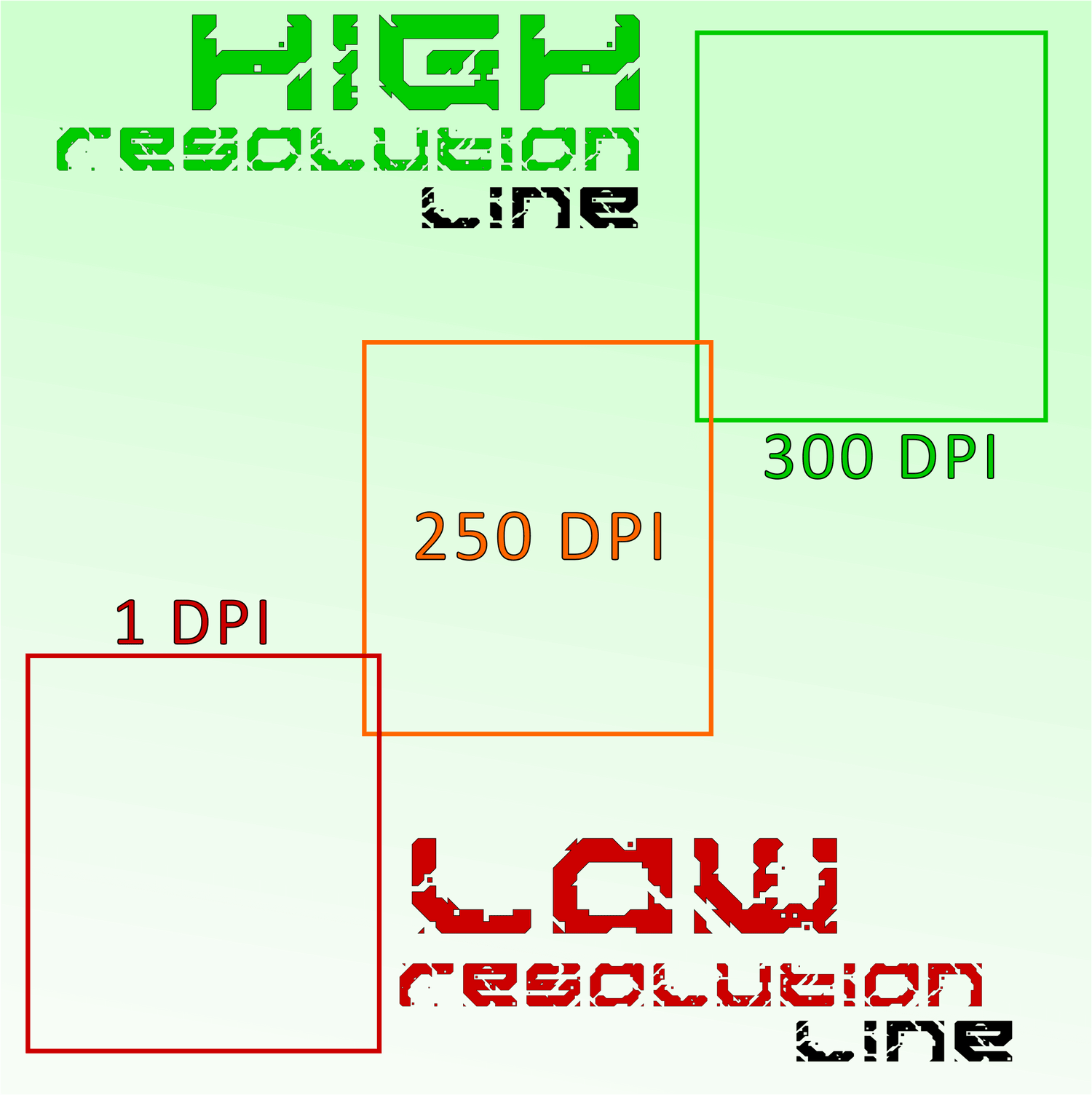

Resolution/DPI Requirements

The minimum required resolution for all designs is 300 DPI ensures clear and sharp prints. Files with a resolution lower than 300 DPI will not be accepted. For professional-quality results, designs should be exported and uploaded at 300 to 1200 DPI. This higher resolution enhances detail and sharpness, making prints appear more refined and photo-like on fabric.

Notes: The more detailed the design, the higher the recommended DPI. However, keep in mind that higher DPI settings increase file size and may require more advanced computer hardware to process efficiently. We can only print as good as the file that you choose to upload. Please select a DPI in the range of 300 - 1200 DPI.

Check List

✔ An accurate color calibrated IPS monitor or TWZ color matching chart (Warning! Colors may not be exact if not used but still can be printed)

Note: We recommend small test orders on new designs printed by TWZ.

✔ COLOR MODE: for the most accurate color representation in DTF printing, artwork should be created using the CMYK color palette. Since DTF printers are limited to CMYK values, designs made in the RGB color mode may result in slight color variations when printed. To ensure color accuracy, it is essential to convert artwork to CMYK before finalizing the design. Although files in RGB can still be submitted, when printed expect the color outcome not to be exact. Additionally, soft proofing can be applied using a downloadable ICC profile, allowing designers to preview how colors will appear in the final print. Color proofing helps to anticipate any potential shifts in tone and make necessary adjustments before production. By following these best practices, designers can achieve more consistent and high quality results in their DTF prints.

Note: We accept design files in both CMYK and RGB formats. However, please note that designs created in RGB may experience color variations in the final print, as DTF printing is limited to CMYK values. For the most accurate results, we recommend designing in CMYK or converting RGB files before submission.

✔ Design DPI is between 300-1200

✔ Image file must have a transparent background

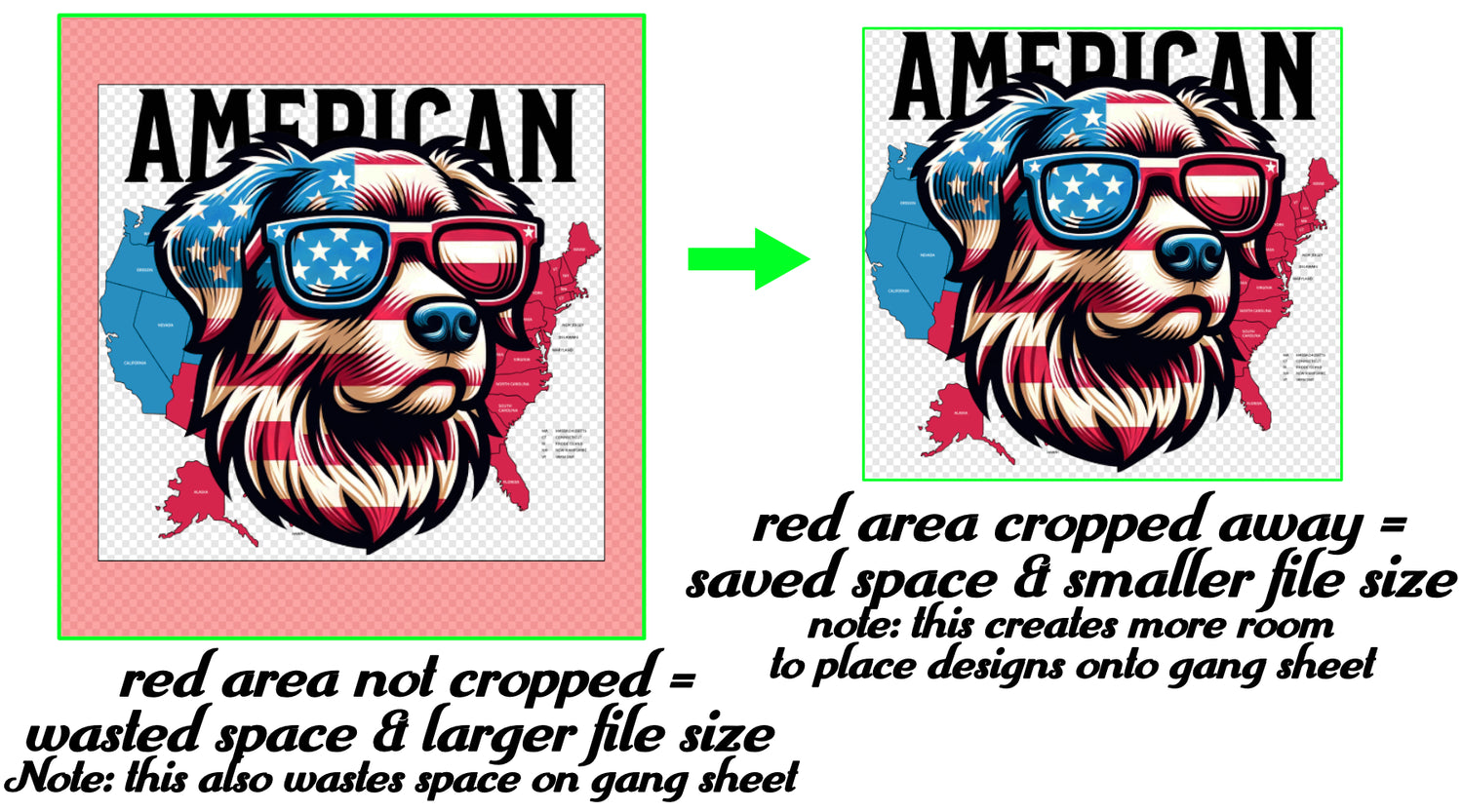

✔ Crop your images to their edges to save space on gang sheets and file size.

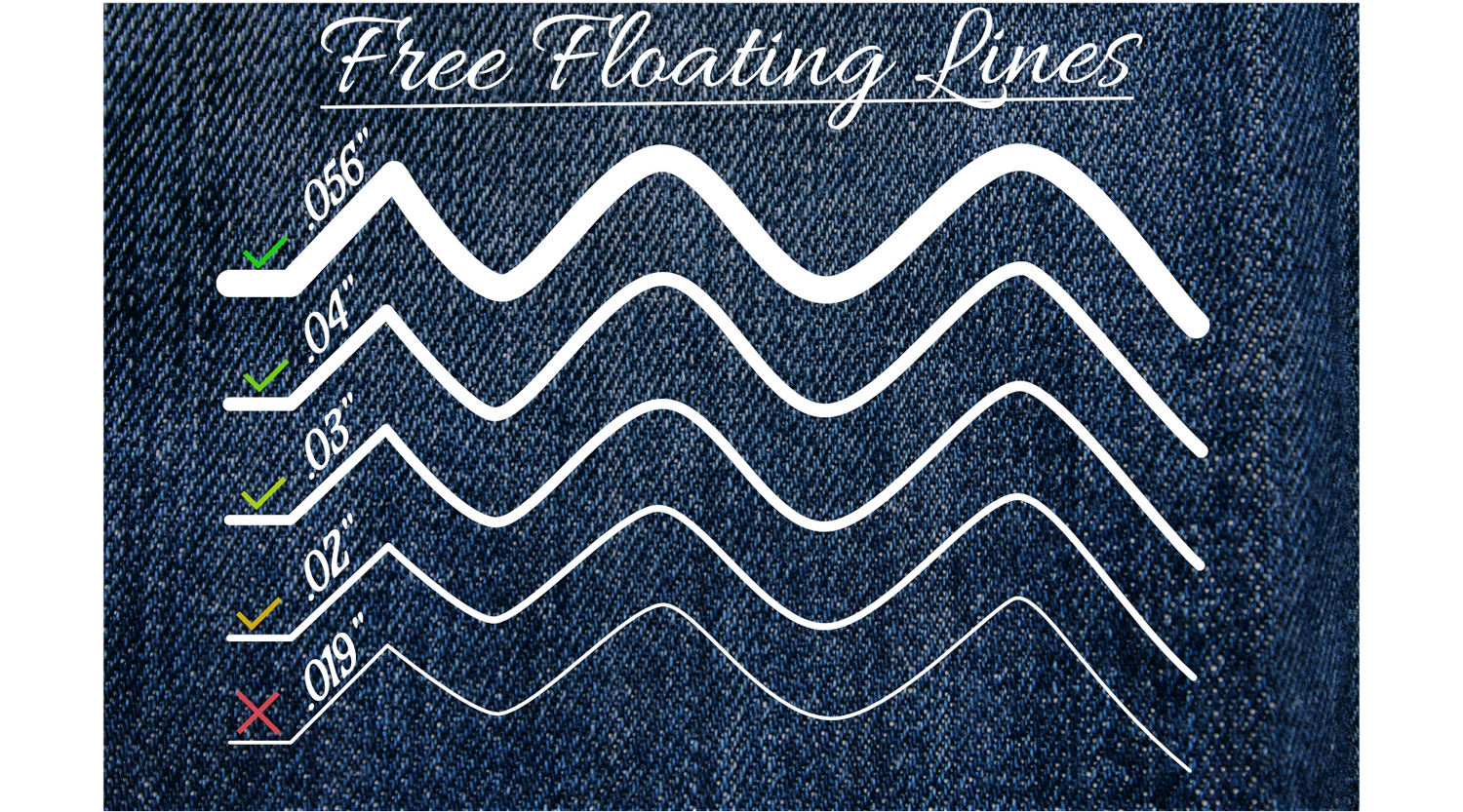

✔ Free floating lines: Any line or segment smaller/thinner than .02" may not adhere to the surface of your garment. all lines should be thicker than .03 for durability".

✔ Mirroring: all mirroring is done by TWZ. please do not submit a mirrored design file.

ALL DESIGNS WILL BE PRINTED AS THEY ARE SUBMITTED. Please ensure that no semi-transparent pixels are present in any file type you submit. Semi-transparent pixels can cause an undesirable white haze effect in DTF production, leading to poor print quality and unsatisfactory production results. Carefully inspect your artwork before uploading to avoid these issues.

Quick list printout

Accepted File Types

Vector types (best) .EPS, .AI, .PDF, .SVG , 's are created with mathematics and can be re-scaled up/down anytime without pixelation.

Raster types (be careful not to stretch files) .PNG, .PSD,'s are created with pixels and cannot be resized without creating pixelated edges. They can only be resized in design software at the time of creating a new file. Semi-transparent pixels will lead to a printed white haze around the design. This is not ideal and looks unpleasant.

Apply a threshold on your design to remove all semi-transparent pixels.

Don't Stretch & Resize Raster files

Stretching & Resizing raster files causes white haze print defect with ( .PNG, .PSD)

All raster images should be sized in design software at the beginning of the artwork design. DO NOT! stretch a raster file in the builder to fit the gang sheet! Stretching raster images can cause semi-transparent edges, lowers DPI, and causes white haze effect which is not ideal for DTF printing. Semi-transparent pixels will cause a white haze to print around the design which is not ideal or appealing. IF YOUR DESIGN HAS SEMI-TRANSPARENT EDGES A THRESHOLD SHOULD BE APPLIED TO REMOVE ALL SEMI-TRANSPARENT EDGES BEFORE PRINTING. Anything lower than a resolution of 300 DPI will also be subpar.

Notes: When starting to create your designs in your chosen software. Make sure your raster file size is proper before creating it in software. On the other hand vector files can be stretched without image, quality loss, and without introduction of semi-transparent pixels. WE STRONGLY ADVISE USING ONLY VECTOR FILES TO AVOID INTRODUCTION OF SEMI-TRANSPARENT PIXELS THAT CAN HAPPEN WHEN RESIZING RASTER FILES.

Image Resolution

For the best print quality, ensure your design is set to 300 DPI or higher (maximum 1200 DPI). In the gang sheet builder, the resolution line indicates image quality—green signifies high resolution, while red indicates low resolution.

Both raster and vector images at 300 DPI or higher will produce sharp, high-quality DTF prints. Files below 300 DPI will not be accepted as they do not meet the required standards for DTF production.

To prevent pixelation, always set your original design file to at least 300 DPI (maximum 1200 DPI). Please save and submit only files that meet this resolution requirement for optimal print results.

Note: The gang sheet builder provides a real-time resolution check, using a color-coded line to indicate whether your image meets the required quality standards, as shown in the example image

Line Width Required

In DTF printing, the minimum line thickness required for durability and proper adhesion depends on factors such as film quality, adhesive powder application, and heat press settings. Lines thinner than 0.5 mm (0.02 inches) may become brittle, break, or fail to adhere properly.

For optimal results, it is recommended to maintain a minimum line thickness of 0.75 mm (0.03 inches) to ensure durability and adhesion. Extremely fine details may not retain enough adhesive powder, leading to adhesion failure. Any lines or segments thinner than this may not adhere properly, increasing the risk of peeling over time or disappearing in the final print. Conducting test prints on different materials is essential to determine the best minimum thickness for your specific setup.

Transparent Background

We do not remove backgrounds from submitted artwork. If your design uploads into the gang sheet builder with a white background, it is incorrect and must be corrected before submission. To ensure proper transparency, your design should display a gray transparent grid behind it, confirming that the background has been completely removed. Make sure to erase any white background, edges, or stray areas before submitting your file. Use design software such as Photoshop, Illustrator, or Canva to export your artwork as a transparent PNG file. Incorrect submissions with backgrounds will not be processed, so please double-check your artwork before uploading to ensure the best print quality.

Notes: In this example the background that is black represent a white background image. While the grey grid represents a transparent back ground.

CMYK Color & Color Matching

DTF Printers are limited to CMYK colors.

When creating your designs in your design program, use CMYK color palette to color your designs for a more accurate representation of your designs colors. Designs submitted in different color profiles (example RGB) may misrepresent design color outcome. Download & use our CMYK ICC profile for accurate colors/ proofing. DTF PRINTING IS LIMITED TO COLORS IN THE CMYK RANGE. Restart design software after setting up ICC profile. The ICC profile is a set of data that characterizes a color input or output device. IPS monitors that are color calibrated with a spectrophotometer are recommended for best results. Without a properly calibrated monitor results will look different before & after printing.

Crop Your Designs

To maximize space when arranging your designs in the gang sheet builder, crop all design files to the actual edges or as close as possible before uploading. This ensures efficient nesting and minimizes wasted space.

Note: Cropping your files before saving also helps reduce file size on your computer

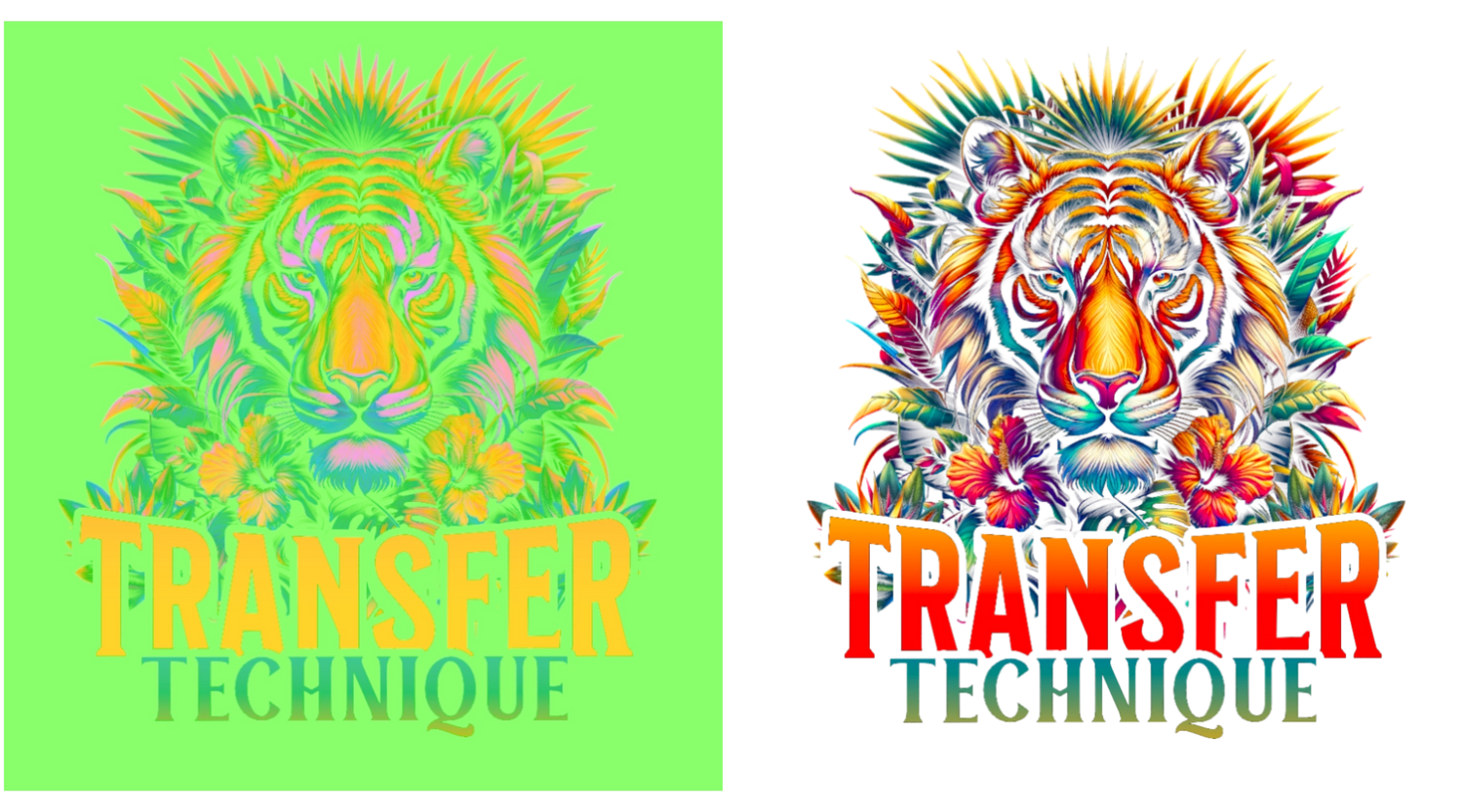

Overall Transfer Feel

DTF transfers can sometimes have a plastic feel, but with the right techniques, you can achieve a softer, more comfortable texture.

Note: the green background square represents the color of the shirt, which in this case will be black. The bright green is used solely for visibility, allowing you to see the design adjustments more clearly. These charts illustrate the progression of techniques used in DTF production to get more professional results. The final outcome will closely match the original design while using less ink, resulting in a softer and more comfortable feel as you move down the chart.

Solid Box - subpar/plastic Feel

A solid box print will not feel as comfortable as a design with intentional spacing or transparency. To achieve the best overall feel, incorporate transparent gaps or distress elements in your design. This allows air to pass through, keeping the print light, breathable, and more comfortable to wear. When submitting large, full-size designs, consider using techniques such as halftoning to enhance comfort and wearability.

Overall Feel: NOT IDEAL

- Not ideal/ plastic feel

- Not breathable

Transparent Background - Better Feel

A transparent background allows the design to blend seamlessly with the fabric, making it look more natural and integrated. You can apply the design to various fabric colors and textures without worrying about the background color clashing or showing through. The design elements stand out more prominently, as there’s no distracting background.

Overall feel: GOOD

- Original design

- Standard DTF feel

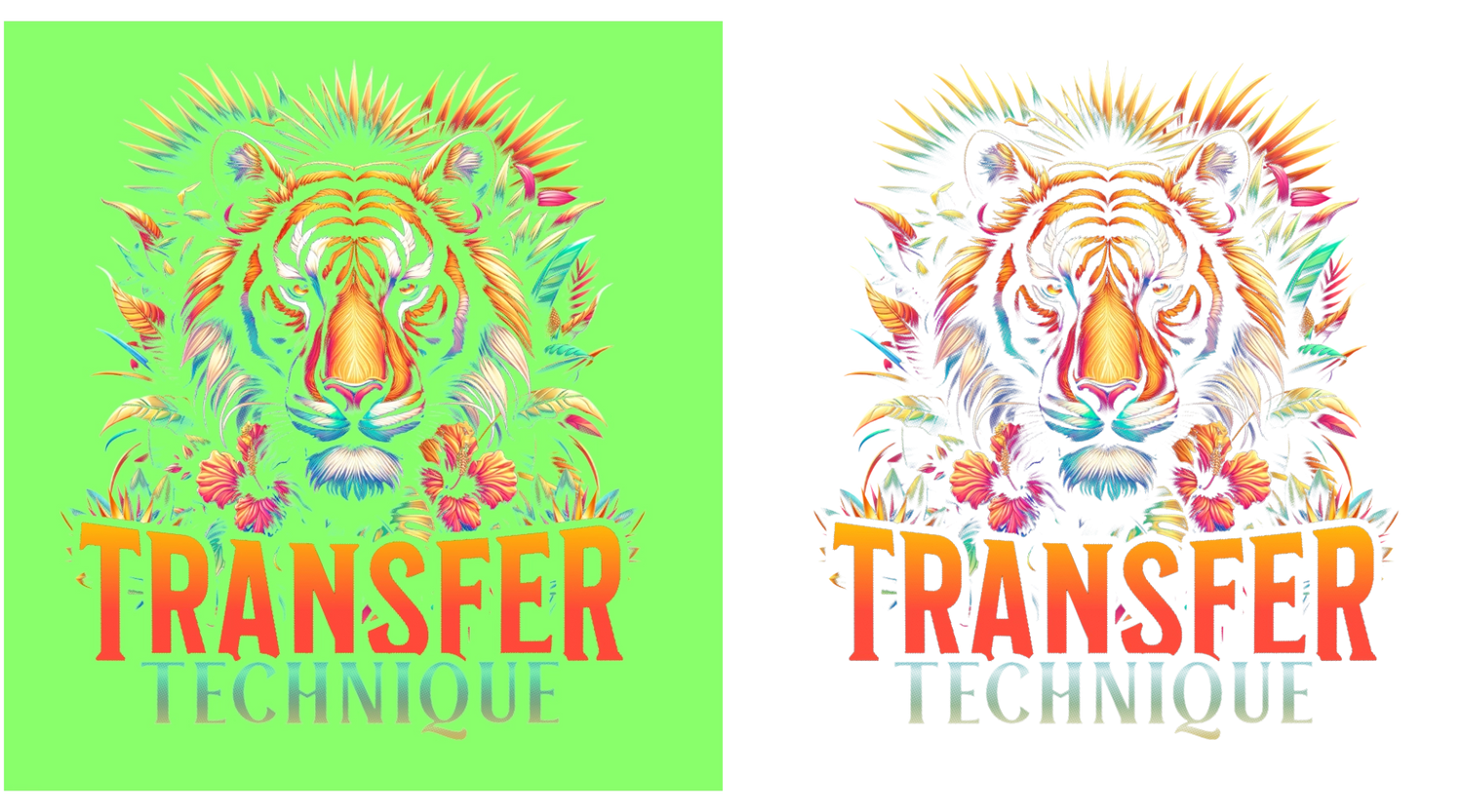

Texture- Adds Style & Air

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.

Overall Feel: GREAT

- Breathable with style

- Various textures can be applied to achieve different visual effects and finishes

Color Knockout - Adds More Air

"Knocking out" colors in DTF (Direct-to-Film) transfers means removing specific colors from your design so that the fabric color shows through, creating a softer hand feel and reducing ink usage.

Overall Feel: GREAT

- Reduces heavyness

- Allows breathability/Air flow

Halftoning - Best Breathability!

Halftoning is a technique used in DTF (Direct-to-Film) printing to create the illusion of continuous tone images using dots of varying sizes and spacing. This method is particularly useful for achieving smooth gradients and blending colors seamlessly with the fabric. Halftoning a design effectively adds maximum breathability to a DTF transfer.

Overall feel: SUPER!

- Best effect for a Light DTF feel

- Reduces heavy-ness max

- Allows maximum breathability/Air flow

- Takes more design effort with trial and error testing

Mirroring

please dont worry about mirroring designs files. all submitted designs are mirrored and printed by TWZ

Inspirational Transfer Idea's

Keep this list handy on a second device to help you with your work flow.

We Care About Your Success

Lets us help you grow your business! You're success is ours.

LETS MAKE T-SHIRTS!

-

DTF transfers fast!

TWZ Transfers are printed with Professional Industrial equipment. We don't print with slow unreliable desktop printers. TWZ Transfers also strives to ship out the same or next business day.

-

The Best Quality

High quality Films, Ink, And adhesives are carefully selected to provide the best transfers the industry can offer. all prints are printed in full color(CYMK) Quality you deserve.

-

Transfers That Beat The Competition.

We inspect our work under a microscope to ensure you're receiving only the best transfers. yes! a microscope. Its also used to achieve proper daily printing alignments and powder applications.

-

Printing Room Temp & Humidity

Our printing rooms are equipped with digital data loggers and controllers to monitor & ensure consistent temperature and humidity levels. Resulting in a consistent printing process with professional results every time.